Design Stage

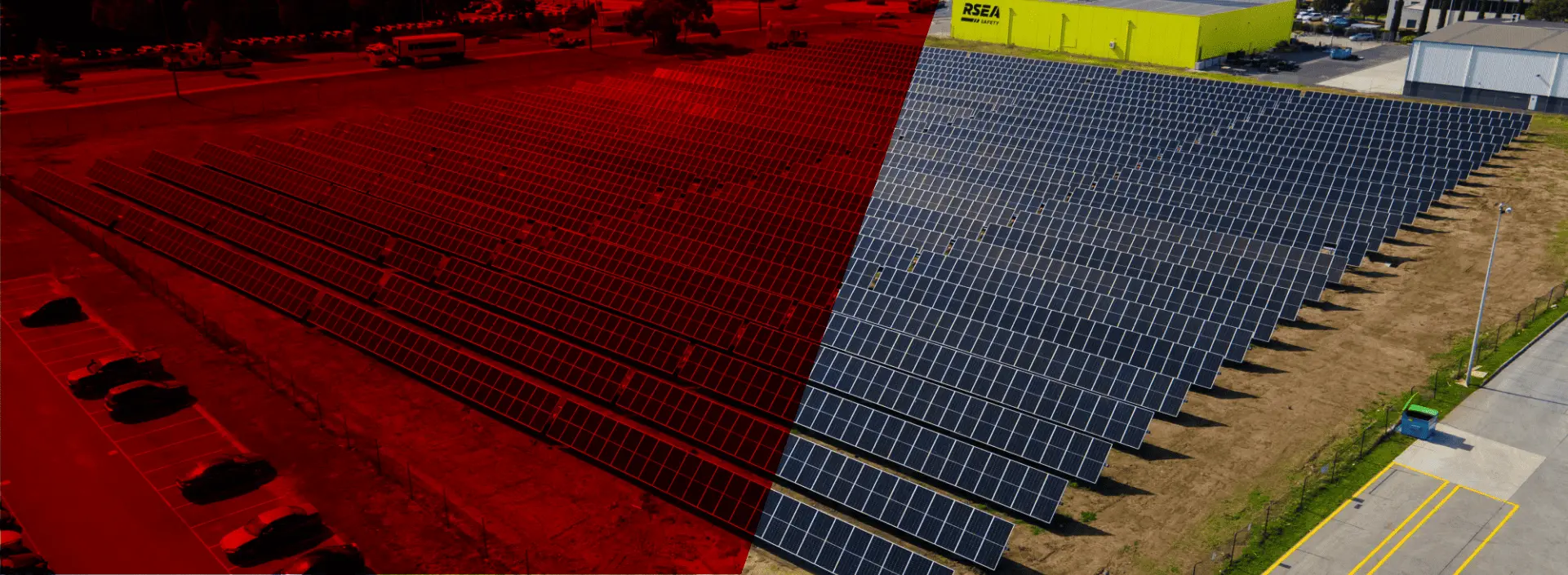

Just like we would with a rooftop, the ground area where the solar panels will be installed needs to be assessed. This is done through a geotechnical study of the ground conditions, which is overseen by structural engineers. The process involves conducting test boreholes at various depths to determine the suitability of the ground for the standard posts (which mount the racking system) and drive posts (which mount the tracking system). Standard post footings need to be 1.2 meters deep and 350 millimetres wide, while drive posts require footings of 1.5 meters in depth and 350 millimetres in width.

Once the ground has been assessed and deemed suitable, we then begin the process of obtaining building and development permits. This crucial step involves liaising with the local council, providing a scope of works, and responding to requests for information, including assessments of environmental impact, effects on local traffic and infrastructure, and conducting a glare and glint study to evaluate potential impacts on pedestrians, motor vehicles, and planes in the vicinity.

Further permits will also be sought for the electrical work, most of which is implemented underground. This includes extensive design work for conduit depths, the required number of pits, and cable spacing to prevent overheating. At this stage, we will also determine the most suitable solar panels and inverters to use across the installation.

Installation Stage

The installation phase begins with trenching at a 200-metre radius to accommodate the cable runs from the solar system to the inverter station. Subsequent trenching is performed for the conduits running from the DC combiner boxes back to the inverter station at the start of each row, totalling approximately 100 meters. The team then proceeds to backfill the trenches.

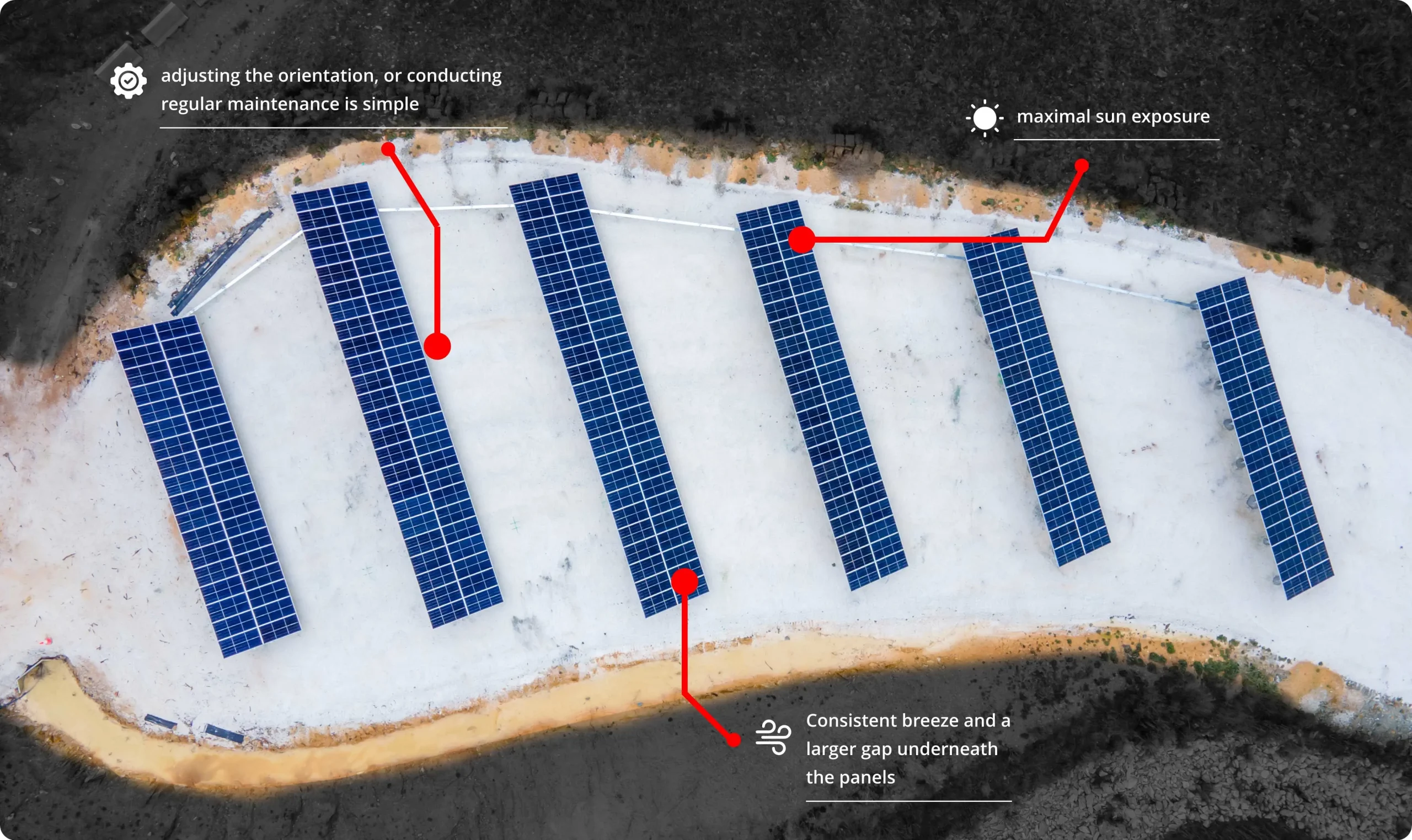

At this stage, post-hole drilling commences based on the layout designed by our engineer. After the holes are excavated, the posts are prepared for concrete filling. After curing, the team assembles the components of the single access tracking system onto the posts, including torque tubes, torque tube brackets, paddles, and panels, which are bolted onto the brackets.

Get Quote

Get Quote Call Now

Call Now