Ellinbank Solar and Battery Storage – Striving toward carbon neutral farming

Ellinbank Dairy Research Centre is a fully functional dairy farm located in Gippsland, Victoria. It’s wholly run by the Department or Jobs, Precincts and Regions to provide valuable research to the industry and assist in making dairy farming more profitable and sustainable within Victoria.

Dairy farming, by its very nature is environmentally taxing. Not only is the processing of milk an energy intensive process, but the livestock themselves contribute to greenhouse gases.

Ellinbank is dedicated to the ambitious goal of becoming a completely carbon neutral farm. So far, they have achieved huge steps toward their target with initiatives such as electric farm vehicles, smart farm management via HALO control software and even raising cows which produce a fraction of the methane.

A sustainable energy source

Part of the next steps the Research Centre took was to reduce their reliance on electricity from the grid. They went to the market seeking a 99kW solar energy system which was combined with a 30kWh battery. This battery was later upsized to 100kWh, making it one of only a small handful in Victoria in that size range.

Kuga Energy won the tender and set about designing the solution. The solution had to be designed such that it was accessible for educational purposes, and that the battery operated in the most effective manner to complement the farms energy usage profile.

Why 99kW solar capacity?

Ellinbank decided on the very specific size of 99.2kW for the solar capacity. This is because in Australia, the Small Scale Technology Certificate (STC) rebate scheme is only applicable to solar energy installations under 100kW in size. At the time of install, the rebate was worth approximately $50,000 – greatly increasing the return on investment.

For this reason 99kW solar installations are very popular in the public and private sector alike.

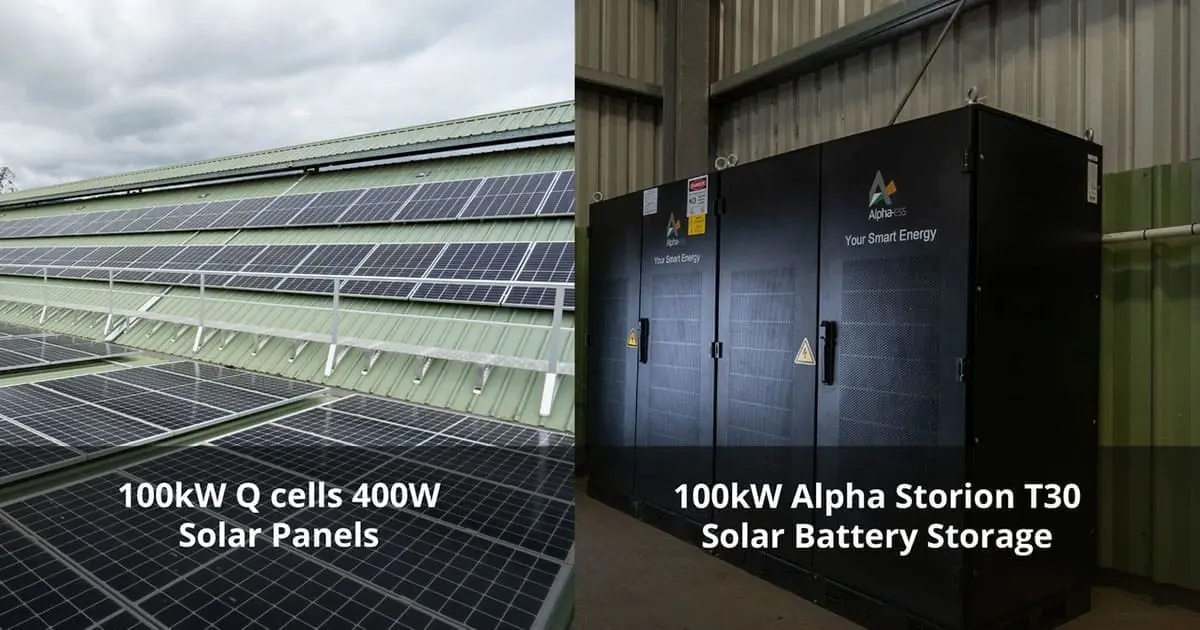

Solar Panels

For this project, Kuga Energy supplied 248 x 400W panels. They recommended Hanwa Q Cell solar panels, a fortune 500 company headquartered in Korea. Q Cells were selected for their over-engineering, value, solid company financials and 12 years’ experience in Australia, more than any other panel manufacturer.

Solar Inverter

To convert the DC power generated by the PV panels into AC power usable by the farm, an inverter needed to be supplied. Ellinbank decided on the Sungrow 110kW inverter. At the time of install, this was one of the only inverters with 100kW capacity. Many of the competing alternatives were only 27.5kW or 50kW increasing the amount of space and complexity required.

Sungrow is the second largest solar inverter manufacturer in the world. The security around local support and proven reliability contributed to its selection for this project.

Battery Storage

Originally, the specification for the project had included zinc-bromine flow batteries. A large part of the spec for this was due to the fact that these were manufactured in Australia. This technology was ultimately dropped in favour of the lithium ion solution offered by Kuga Energy (Alpha-ESS).

Despite being a Chinese company, Alpha ESS have committed to building a very large manufacturing facility in South Australia. As such, they are already subsidised by the SA State Government and will rapidly have increase local presence.

Compared to zinc-bromide batteries, lithium-ion has:

- Significantly more efficient when AC coupled to solar modules

- A higher rate of power release (better for load shedding)

- A smaller and lighter package, increasing suitability to indoor applications and maintenance.

- Lower capital cost

The final battery solution installed by Kuga Energy was the Alpha ESS Storion T 30, with 102kWh of usable storage capacity.

Why battery storage?

Solar energy is a fantastic way to draw clean energy directly from the sun. It is often not possible to match the energy requirements of a commercial farm exactly with the peak production from the sun.

Rather than waste the electricity generated by solar if it is not required, the power gets fed back into the electricity grid, where the owner of the system receives a credit. It is still preferable to use the solar power if possible, because the credit is substantially less than the power costs to buy.

In the case of Ellinbank, it was decided they would prefer to save this valuable clean power and use it at times of peak demand. This reduces electrical costs even further since they get charged based on the maximum electrical draw every month. This is measured in 15 minute intervals. This also reduces the electrical strain on the farms electrical supply, lowering the risk of circuit breakers tripping.

Kugas design team analysed the historical electricity requirements of the farm and programmed a forced discharge of the battery during this time each day. This is a feature known as “load shedding” and further increases the savings produced by a battery storage system.

Getting the most out of the solar and battery

With any roof mounted solar install, there is an element of design and compromise. This is only increased with the installation of a battery unit.

Panel orientation: Solar panels produce the greatest yield when orientated North. At Ellinbank, the largest uninterrupted roof space was the animal house. With roof-mounted solar, there are limited options with size and orientation. In this instance, over half the panels were orientated almost perfectly due North.

Kuga Energy put the remainder of the panels on the Southern section of the roof. This will result in a 12% lower yield compared to optimum. The compromise was justified to Ellinbank in the following way:

- Placing the panels on tilt reduces the total amount of panels which can fit on the roof. This is because each row needs to be spaced apart to prevent shading. The cost of adding tilt and running extra wiring and walkways to the rear of the building would negate the small yield benefits many times over.

Walkways: A major goal of this project was to provide education to industry and students. Solar and storage is now a key consideration for all primary industries. As such, the project needed to allow safe and easy access to understand how PV panels are mounted and arranged on a roof.

Kuga Energy managed the compliant installation of walkways, ladder access, safety warning signs and harness connection points for future expansion works and cleaning.

HALO integration: Most critical systems within the farm are monitored using a centralised system called HALO. This allows processes such as grain feed levels to be monitored and automatically ordered when running low.

Ellinbank wanted the renewable energy system to be integrated into the central HALO software. Provision was made to install monitoring “nodes” at the main switchboard, as well as the local solar distribution board.

This would provide high level monitoring of the solar and battery production. The 110kW Sungrow solar inverter comes with its own monitoring software, which provides more detailed monitoring of the each of the “string” inputs coming from the panels.

Likewise, the alpha battery has its own wifi monitoring. Kuga Energy installed a separate 5G modem to ensure reliable connection to both monitoring systems.

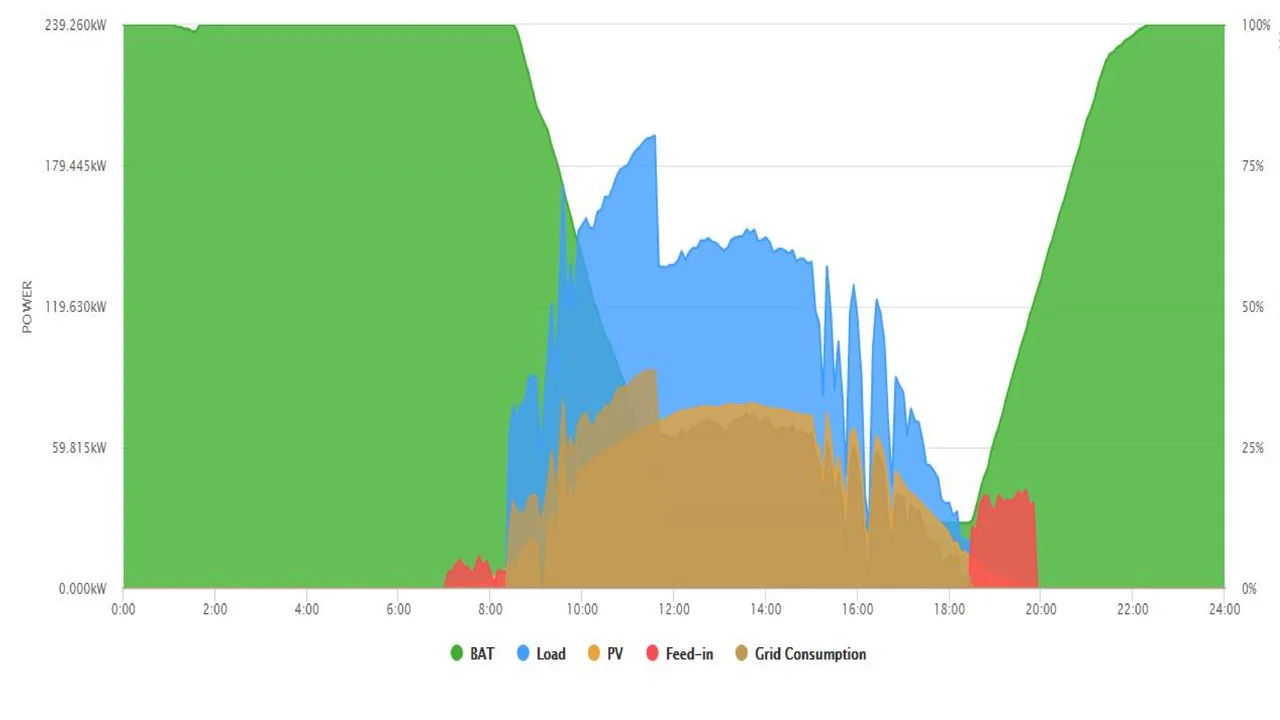

Battery programming: By default, a battery will try and achieve 0kW net flow of power between itself and the grid. This means it is supplying exactly what the demands of the farm are and charges whenever surplus is available.

The farm demands are often far in excess of what the battery can supply. The battery can release its power at a maximum of 30kW. With a storage capacity of 102kWh, the battery will take 3 hours to fully discharge.

Kuga Energy analysed Ellinbanks electricity usage profile and discovered that the peak demand consistently occurred during the two daily milking periods occuring between 6-9m and 4-7pm. As a result, a forced discharge of 20kW was specified during these periods.

A forced charge was specified prior to this from 7am-10am, to ensure the full capacity of the battery was utilised. Note that this would involve taking some power from the grid, but this is still cheaper than the peak demand charges.

This created an immediate increase in projected savings due to the reduction in peak demand charges on the monthly bill.

Diesel Generator compatibility: It is a common misconception that battery storage can be used in place of a generator. While battery can provide valuable backup, this is typically limited to critical but low draw applications such as servers.

Kuga Energy installed a radio-controlled switch which senses when grid power is off & the diesel generator comes on. This shuts the solar and battery off completely. The reverse happens when power is restored.

Ongoing optimisation and maintenance

Battery optimisation: The electricity usage of the farm will be monitored to identify what changes occur with seasons, new technology initiatives such as EV charging etc.

The Storion T30 battery can be programmed to change settings based on certain dates to account for seasonality or changes in production.

Maintenance: One of the attractive aspects of investing in solar energy is the very low ongoing maintenance. Ellinbank was provided with the recommended three and six-monthly checks and inspections.

There is no prescribed preventative maintenance involved with the installation of a solar or Li-ion battery system. The monitoring allows for reactive maintenance such as cleaning of PV panels. For a farm, a maintenance free energy solution is one less think to worry about.

Ellinbank will continue to monitor and optimise their renewable energy system as they continue to strive for a 100% carbon neutral site. The system will provide education and hopefully encourage other farm owners in the Gippsland to uptake renewable solutions into the future.

Get Quote

Get Quote Call Now

Call Now